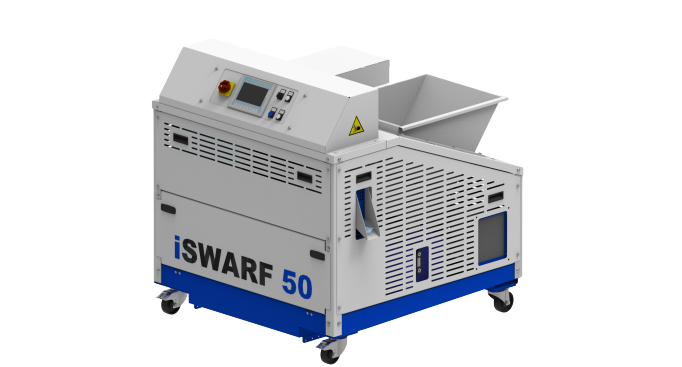

iSwarf 50

iSwarf 50 is briquetting press for metal chips, can be offered as a standard accessory to the machining centre. Small and compact briquetting press, suitable for direct placement under the conveyor of machine chips or as a freestanding press for manual loading. Press can be easily moved thanks to wheels on bottom. Very easy start up and settings of the press thanks to renommed simple control system Siemens.

.jpg)

Briquette diameter

Pump input

Output (aluminium)

Installed input

Specific gravity of the briquette

Hopper

Dimensions

Weight

Pump input

Output (aluminium)

Installed input

Specific gravity of the briquette

Hopper

Dimensions

Weight

60 mm

4 кW

30 кg/h

4,5 кW

1000-2000 кg/m3

0,1 m3

1360x1180x1390 mm

780 кg

4 кW

30 кg/h

4,5 кW

1000-2000 кg/m3

0,1 m3

1360x1180x1390 mm

780 кg

SIEMENS SIMATIC HMI

+ Simple press start-up

+ Easy press parameters settings

+ Easy press status monitoring (pressure, briquettes counting, running hours, easy

diagnostics for the servis and maintenance)

+ Standart languages: czech, english, german, russian

+ Simple press start-up

+ Easy press parameters settings

+ Easy press status monitoring (pressure, briquettes counting, running hours, easy

diagnostics for the servis and maintenance)

+ Standart languages: czech, english, german, russian

+ Sensor of material level in the hopper

+ Long chips shredder

+ Long chips shredder

Benefits:

+ Compact, simple and reliable machine design

+ Easy operation and maintenance

+ Simple installation and machine manipulation

+ possibility to equip the machine with additional module to process the long swarfs

+ Compact, simple and reliable machine design

+ Easy operation and maintenance

+ Simple installation and machine manipulation

+ possibility to equip the machine with additional module to process the long swarfs

iSwarf 50 offers:

+ Increases the price of produced swarfs and chips

+ Reduces the volume of produced swarfs in place of its production in ratio up to 1:10

+ Reduces the frequency of swarfs and chips disposal from machining center, other

manipulations and transport in general

+ Separates the fluids contained in material and allows of its reuse

+ Increases the cleanliness of work environment

+ Reduces the risk of ecological pollution by oil substances leaked from swarfs and chips

+ Eliminates the requirement for central swarf conveyor system

+ Increases the price of produced swarfs and chips

+ Reduces the volume of produced swarfs in place of its production in ratio up to 1:10

+ Reduces the frequency of swarfs and chips disposal from machining center, other

manipulations and transport in general

+ Separates the fluids contained in material and allows of its reuse

+ Increases the cleanliness of work environment

+ Reduces the risk of ecological pollution by oil substances leaked from swarfs and chips

+ Eliminates the requirement for central swarf conveyor system

Benefits

+ Press can be located directly under the chip conveyor of

machining centre

machining centre

+ Press can stand alone in the hall and be filled manually

Press placement

aluminium

cast-iron

steel

other materials

Your sample

?

?

Material suitable for briquetting

Output

around...………... 30 кg/h

(Output depends on detailed specific of the material, briquetting test is all time recommended)

around...………... 30 кg/h

(Output depends on detailed specific of the material, briquetting test is all time recommended)

Output

around...………... 80 кg/h

(Output depends on detailed specific of the material, briquetting test is all time recommended)

around...………... 80 кg/h

(Output depends on detailed specific of the material, briquetting test is all time recommended)

Output

around...………... 80 кg/h

(Output depends on detailed specific of the material, briquetting test is all time recommended)

around...………... 80 кg/h

(Output depends on detailed specific of the material, briquetting test is all time recommended)

If you want to briquette any other material we will conduct a free test after receiving a sample of material weighing at least 50 kg

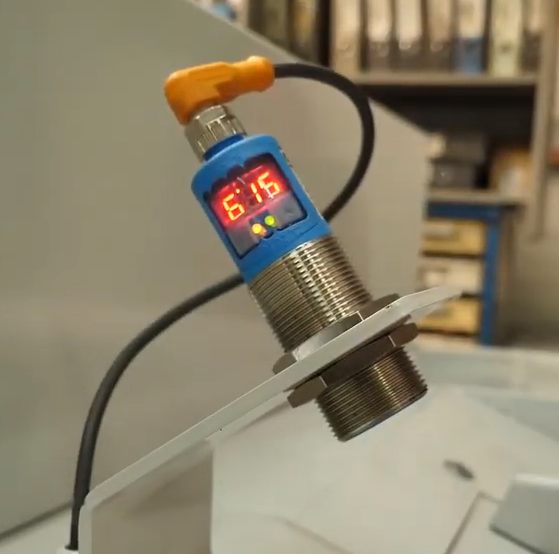

+ Sensor of material level in the hopper

This option is required, if the press will be filled with chips automatically - for example when the press is located directly under the chip conveyor of the machining centre. When the press hopper is full sensor automatically stop chip conveyor, when the material level in hopper goes down, conveyor will automatically start filling press with chips again.

This option is required, if the press will be filled with chips automatically - for example when the press is located directly under the chip conveyor of the machining centre. When the press hopper is full sensor automatically stop chip conveyor, when the material level in hopper goes down, conveyor will automatically start filling press with chips again.

Available options

+ Long chips shredder

This option is required in the case of briquetting long chips (usually longer than 5cm) and chips which creating bunches. The shredder is fully controlled from the control panel of the machine, where you can directly turn on / off the crusher, set the desired automatic mode of operation and rest time, set the reverse or alternate rotation of the crusher shafts.

This option is required in the case of briquetting long chips (usually longer than 5cm) and chips which creating bunches. The shredder is fully controlled from the control panel of the machine, where you can directly turn on / off the crusher, set the desired automatic mode of operation and rest time, set the reverse or alternate rotation of the crusher shafts.

Videos

.png)