Options

- Line examples

- Lifting device

- Chip conveyors

- Containers/stacks

- Sorters/Separators

- Chip crushers/shredders

- Centrifuge

- Weighing-machine

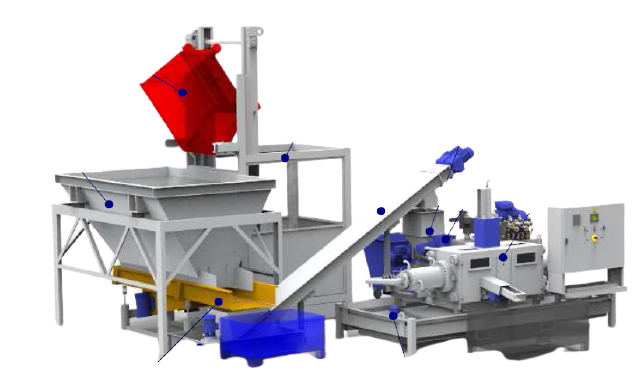

Line:

1) Lifting equipment

2) Chip container

3) Chip conveyor

4) Press BrikStar MD15

1) Lifting equipment

2) Chip container

3) Chip conveyor

4) Press BrikStar MD15

Line:

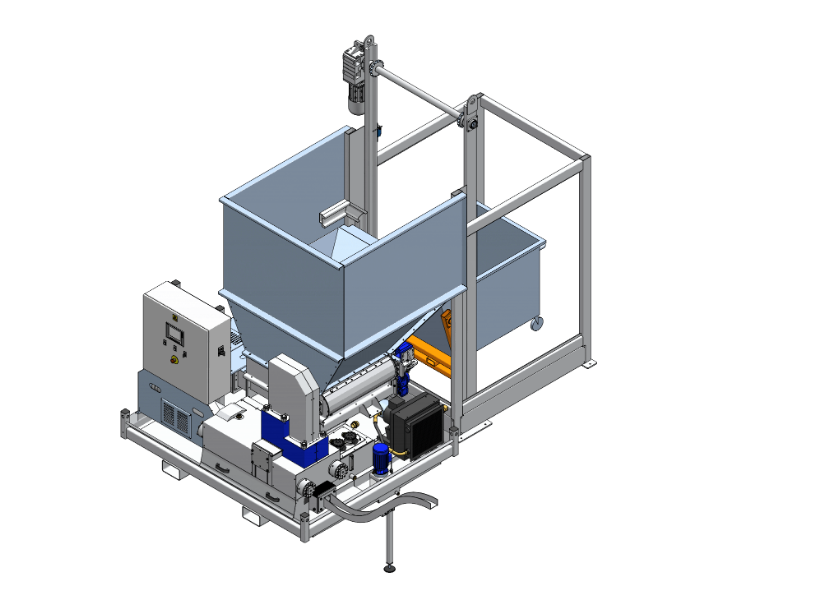

1) Lifting equipment

2) Press iSwarf 550

1) Lifting equipment

2) Press iSwarf 550

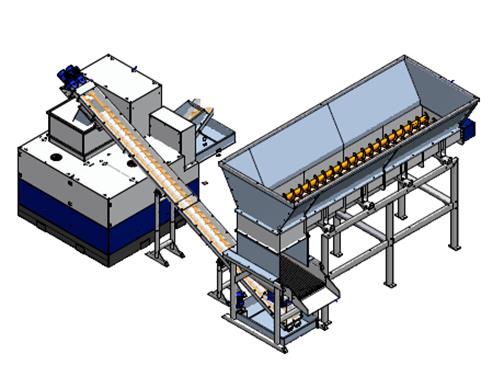

Line:

1) Chips stacks

2) Chip conveyor

3) Chip conveyor

4) Press iSwarf 800

5) Finished briquette conveyor

6) Vibration sorter

1) Chips stacks

2) Chip conveyor

3) Chip conveyor

4) Press iSwarf 800

5) Finished briquette conveyor

6) Vibration sorter

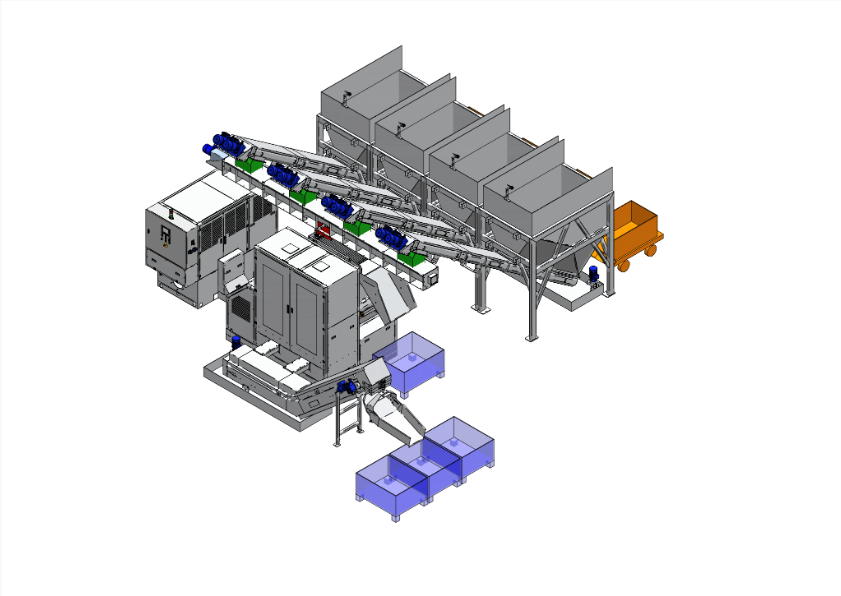

Line:

1) Chip stack container

2) Chip conveyor

3) Vibration sorter

4) Distributive chip conveyor for

filling two presses

5 - 6) Press BrikStar

1) Chip stack container

2) Chip conveyor

3) Vibration sorter

4) Distributive chip conveyor for

filling two presses

5 - 6) Press BrikStar

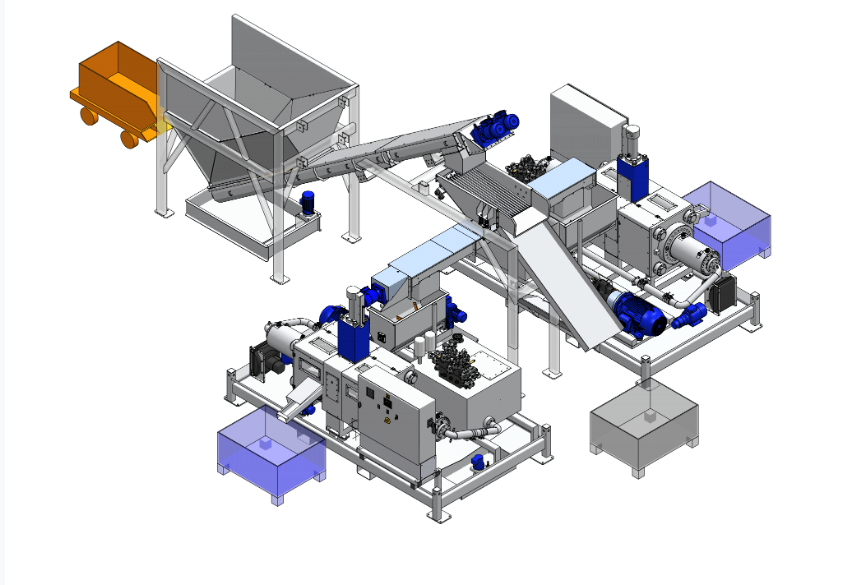

Line:

1) Lifting equipment

2) Chip crusher

3) Vibration sorter

4) Chip conveyor

5) Chip stack

6) Centrifuge

7) Chip conveyor

8) Press iSwarf 550

1) Lifting equipment

2) Chip crusher

3) Vibration sorter

4) Chip conveyor

5) Chip stack

6) Centrifuge

7) Chip conveyor

8) Press iSwarf 550

Line:

1) Chip stack for crane filling

2) Vibration sorter

3) Chip conveyor

4) Press iSwarf 800

1) Chip stack for crane filling

2) Vibration sorter

3) Chip conveyor

4) Press iSwarf 800

Lifting device VZ 800

Is determined for automatic, safe and effective manipulation with chips in containers, for example for filling the hopper of briquetting press with chips or for delivering long chips to the crusher.

Can be the part of briquetting presses produced by company BRIKLIS or can be delivered alone machine with own electric cabinet for connecting to other machines. Easily modifiable construction solution of lifting equipment allows adaptation to individual customer's shipping containers and the required tipping height.

VZ 800 meets high safety standards

It can be equipped with these safety features:

+ light signalization

+ tanks for catching liquids from metal chips

+ ramps and anti-skid grids

+ mirror which allows to the operator easy visual control of tipping area

+ integrated fences with definated entrance to the working area for changing containers for chips

+ safety light barrier which secures the containers weighing area. This solution lowering the time of container input, because there is no need to open and close doors in safety fence.

Is determined for automatic, safe and effective manipulation with chips in containers, for example for filling the hopper of briquetting press with chips or for delivering long chips to the crusher.

Can be the part of briquetting presses produced by company BRIKLIS or can be delivered alone machine with own electric cabinet for connecting to other machines. Easily modifiable construction solution of lifting equipment allows adaptation to individual customer's shipping containers and the required tipping height.

VZ 800 meets high safety standards

It can be equipped with these safety features:

+ light signalization

+ tanks for catching liquids from metal chips

+ ramps and anti-skid grids

+ mirror which allows to the operator easy visual control of tipping area

+ integrated fences with definated entrance to the working area for changing containers for chips

+ safety light barrier which secures the containers weighing area. This solution lowering the time of container input, because there is no need to open and close doors in safety fence.

Screw conveyors

Technical parameters

Screw conveyors are produced from steel trough with covers and cylindrical screw welded to the tube. For very abrasive materials is possible to make trough and screw from Hardox. In trough can be placed one or two screws. Trough is equipped with sieve for liquid evacuation from chips to the tank.

Diameters from 120 to 160 mm

lenght to 6000 mm

Benefits

+ optimal dimensions for technology location

+ tow-screwed solution is optimal for longer chips

+ dust free transport of material

Technical parameters

Screw conveyors are produced from steel trough with covers and cylindrical screw welded to the tube. For very abrasive materials is possible to make trough and screw from Hardox. In trough can be placed one or two screws. Trough is equipped with sieve for liquid evacuation from chips to the tank.

Diameters from 120 to 160 mm

lenght to 6000 mm

Benefits

+ optimal dimensions for technology location

+ tow-screwed solution is optimal for longer chips

+ dust free transport of material

Chips stacks

Stacks for metal chips are produced in different sizes to the volume of 14 m3. Can be equipped with the vibration bottom or assembly of 4 to 6 screws for material evacuation regarding to properties of pressed materials.

Design

Stack with four screw conveyors

Is optimal for stocking and manipulating with the longer chips which are not bulk but it is easy to split them. Bottom of the stock is equiped with assembly of four screw conveyors with different rotations and diameters. Stack is situated close to the press. Small type of stocker, 0,6 m³, with possibility to equip with pressing cylinder WA or separating cylinder WE for metal briquetting presses.

Stack with vibrating bottom with volume from 2 to 14 m³

Is optimal for stocking chips. Material is transported with tipping containers or with the loader. A part of bottom is a sieve for separation of other pieces of waste. Stocker is installed close to the press also is possible to locate stocker outside under the ground level.

Stacks for metal chips are produced in different sizes to the volume of 14 m3. Can be equipped with the vibration bottom or assembly of 4 to 6 screws for material evacuation regarding to properties of pressed materials.

Design

Stack with four screw conveyors

Is optimal for stocking and manipulating with the longer chips which are not bulk but it is easy to split them. Bottom of the stock is equiped with assembly of four screw conveyors with different rotations and diameters. Stack is situated close to the press. Small type of stocker, 0,6 m³, with possibility to equip with pressing cylinder WA or separating cylinder WE for metal briquetting presses.

Stack with vibrating bottom with volume from 2 to 14 m³

Is optimal for stocking chips. Material is transported with tipping containers or with the loader. A part of bottom is a sieve for separation of other pieces of waste. Stocker is installed close to the press also is possible to locate stocker outside under the ground level.

.jpg)

Sorters and separators

Vibrating sorter of big pieces

Vibrating sorters are own production and safely separate pieces of other materials with bigger dimensions which are not suitable for briquetting and which are bigger than the slots between vibrating shafts.

Vibrating sorter of big pieces

Vibrating sorters are own production and safely separate pieces of other materials with bigger dimensions which are not suitable for briquetting and which are bigger than the slots between vibrating shafts.

Magnetic separator

For separating magnetic (ferrous) materials from aluminium chips we are using the permanent magnet mounted over the conveyor for chips. For automatic cleaning, the magnet can be equipped with belt conveyor.

For separating magnetic (ferrous) materials from aluminium chips we are using the permanent magnet mounted over the conveyor for chips. For automatic cleaning, the magnet can be equipped with belt conveyor.

Metal crushers for editing of chip sizes before briquetting

Material which contains long and voluminous chip, is necessary to crush to the optimal size.

Material which contains long and voluminous chip, is necessary to crush to the optimal size.

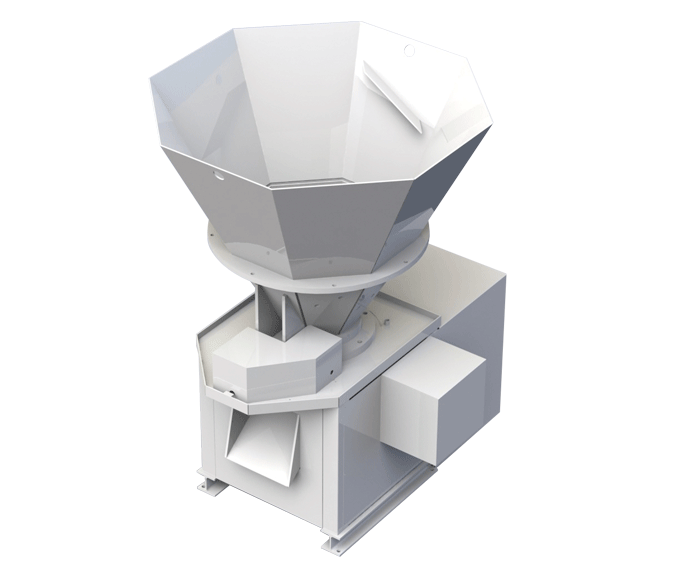

Chip crusher SCR - 20

Chip breaker ARTEP

The chips are fed into a hopper at the top of the crusher. Some knives are screwed to the sides of the tapered hopper and a feed arm pushes the chips towards these knives for pre-chopping.

Then the chips are crushed at the bottom of the conical hopper, where a crushing head with a crushing ring is installed for this purpose.

The SCR model crusher is equipped with a special device called "BAR END EJECTOR" to eject random solid particles or rod ends between the chips. Rod end pusher dimensions: 105 x 60 mm.

Тechnical data:

Then the chips are crushed at the bottom of the conical hopper, where a crushing head with a crushing ring is installed for this purpose.

The SCR model crusher is equipped with a special device called "BAR END EJECTOR" to eject random solid particles or rod ends between the chips. Rod end pusher dimensions: 105 x 60 mm.

Тechnical data:

| Type: | SCR-20 |

| Power: | 15 kW |

| Output*: | 1000 kg / h (Steel) 400 kg / h (Aluminium) |

| Height: | 2080 mm |

| Dimensions: | 1670x1050 mm |

| Producer: | Indass, Italy |

The shavings spontaneously fall into the crushing chamber, in which two rotating rollers with crushing toothed discs are located in parallel. As soon as the long chips enter the space between the grinding rolls, they are crushed by toothed discs to the required fraction suitable for briquetting. Grinding takes place between special screws that rotate away from each other and break the material. Separate large pieces through a sieve. When ARTEP detects that a large piece has overloaded the auger gearbox, the sieve opens automatically and the large piece falls out. Then the crushed shavings fall along the shaft into the hopper, from where they are transported by the conveyor into the hopper of the briquetting press.

Теchnical data:

Теchnical data:

| Type: | ARTEP |

| Power: | 1,6 kW |

| Output*: | 500 кг / ч (Steel) 300 кг / ч (Аluminium) |

| Dimensions: | 1600x1000x200 mm |

| Weight: | 1250 kg |

| Producer: | Briklis, Czechia |

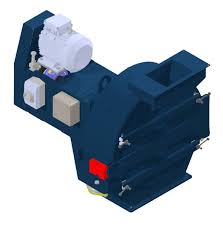

Centrifuge HD 50

In a horizontal chip centrifuge, the coolant and the chips are separated in a horizontally suspended drum, where the coolant is separated by a tapered rod. The chip centrifuge is completely emptied even after switching off. With the highest centrifugal force centrifuges on the market, you will achieve the best separation between scrap metal and refrigerant.

The centrifuge is ideal for continuous processing and operates without manual control. It can handle any chip shorter than 30 mm.

Weight: 600 kg

Capacity: 3-600 kg

In a horizontal chip centrifuge, the coolant and the chips are separated in a horizontally suspended drum, where the coolant is separated by a tapered rod. The chip centrifuge is completely emptied even after switching off. With the highest centrifugal force centrifuges on the market, you will achieve the best separation between scrap metal and refrigerant.

The centrifuge is ideal for continuous processing and operates without manual control. It can handle any chip shorter than 30 mm.

Weight: 600 kg

Capacity: 3-600 kg

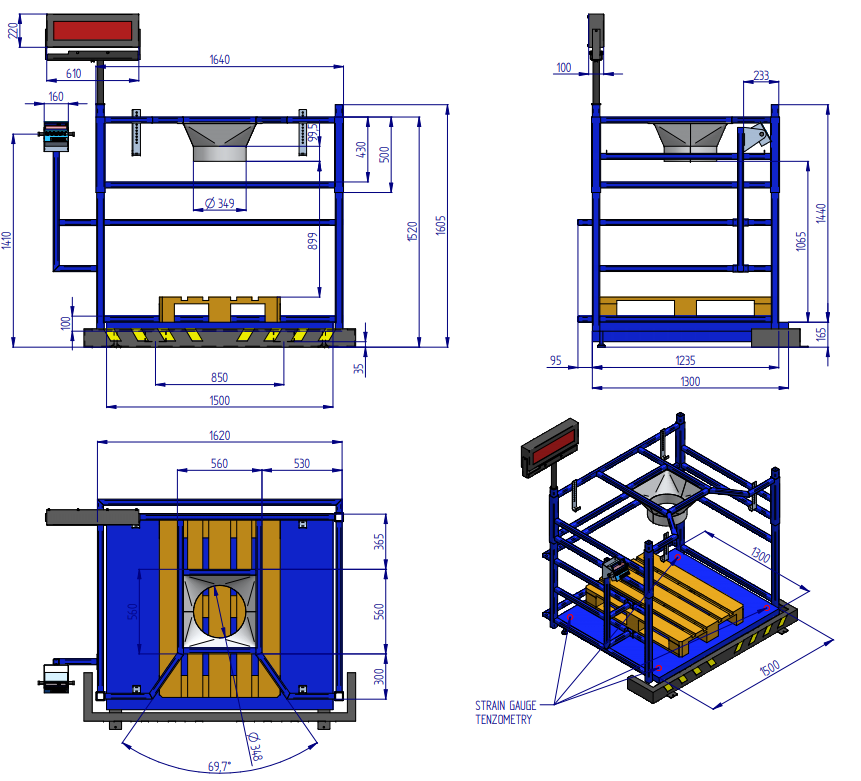

Big bag weight

The scale is a weldment of steel profiles and sheets with the dimensions of the lower platform 1500x1300mm (pos.4.). Weighing takes place using shear strain gauges located in adjustable support legs (pos.3). A structure with a height-adjustable superstructure (pos. 5) and with a hopper for directing briquettes (pos. 7) into a BIGBAG bag (pos. 10) is welded to the platform. To adjust the weight according to the dimensions of the bags, there are also 4 hanging hooks (pos. 6), which are used for hanging and centering the empty bag, they are not supporting elements. The scale construction also includes holders with the DGT20 control unit (pos. 1) and a large-area information panel (display) Formatic Jumbo (pos. 2). The steel protective frame (pos. 8) is firmly anchored to the floor and serves to prevent shifting and possible damage to the scale.

The scale is a weldment of steel profiles and sheets with the dimensions of the lower platform 1500x1300mm (pos.4.). Weighing takes place using shear strain gauges located in adjustable support legs (pos.3). A structure with a height-adjustable superstructure (pos. 5) and with a hopper for directing briquettes (pos. 7) into a BIGBAG bag (pos. 10) is welded to the platform. To adjust the weight according to the dimensions of the bags, there are also 4 hanging hooks (pos. 6), which are used for hanging and centering the empty bag, they are not supporting elements. The scale construction also includes holders with the DGT20 control unit (pos. 1) and a large-area information panel (display) Formatic Jumbo (pos. 2). The steel protective frame (pos. 8) is firmly anchored to the floor and serves to prevent shifting and possible damage to the scale.

| Dimensions of working platform: | 1500x1300 mm |

| Maximal weighability: | 1996 kg |

| Outside working temperature: | 15 - 30 °C |

| Working place humidity: | 40 - 70 % |

| Supply voltage: | 230 V |

| Communication bus: | RS 485 |

| Strain gauges - weight sensors: | 4x cut, type SBX2000-1KL - *) |

| Weight: | 410 kg |

| Formatic Jumbo display size - size of digits (text): | 515 - 124 mm (100) |

| Recommended size of BIGBAGs: | 900x900x680 mm |

| Dimensions: | 2140x1505x1605 mm |

| Recommended expansion anchors for anchoring the frame to the floor: | 4x Hilti HSA-R2 M12x115 |

Теchnical data:

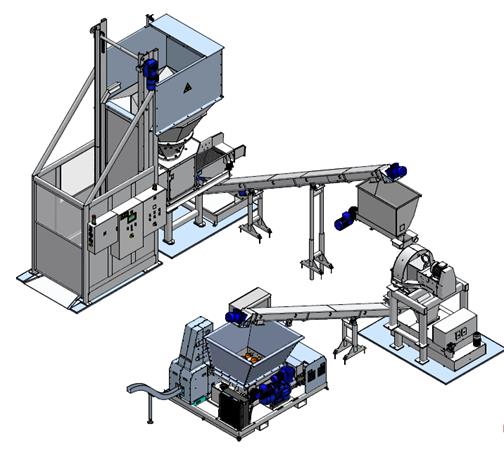

Automatization

Our company offers not only briquetting presses, but also a comprehensive solution for automatic lines for the preparation and transport of chips before the briquette pressing. Each automated line and its composition is solved individually exactly by the specific requirements or needs of the customer. The lines are a modular system, so the layout of the individual elements of the line can be adapted to specific spaces in the workshop. For easy setup and line control, all line elements are controlled by a central control panel from one place.

.png)